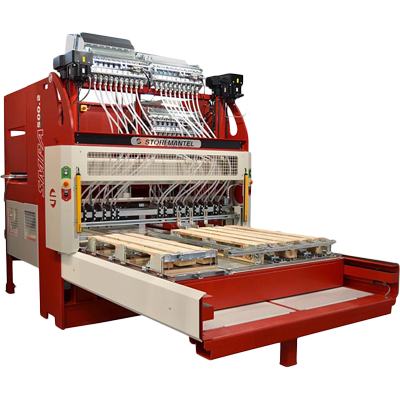

Description

Modern solid wood processing technologies using the FLS ARROW II single-disc spreading saw significantly increase yield, productivity and enhance the quality of the wood mass. Of course, great emphasis is placed on the quality of the cut and ease of use. The highly versatile FLS ARROW I saw is also used mainly in small and medium-sized operations. PRISMA, planks, prisms and large-area material can also be cut on the FLS ARROW I saw. Input materials can be plastered, scattered, formatted, blanks and slats produced. It is also possible to cut obliquely and miter. The advantage of the machine is the high speed and accuracy of individual cuts and a high degree of flexibility of input and output dimensions of the processed material. FLS ARROW Aj is appreciated in pillar production, in furniture workshops, in the production of semi-finished products for windows, doors and stairs. He also works successfully in the processing of large-area materials, in carpentry plants and in the production of wooden structures. The machine can also be used for cutting non-wooden materials, e.g. PUR panels, sandwich panels, plastic boards, aluminum boards, etc. Of course, there are safety features that ensure safe work on the spreading saw. The machine meets the strict requirements for work safety, resulting from the relevant regulations and EC directives.

Material processing options for FLS ARROW II sawmill

Saw arrangement and principle

The material to be cut, loosely seated on the work table, is a longitudinal cut with a movable saw blade. At the end of the cut, the saw blade slides under the saw table and returns to the starting position. At the same time, the rear longitudinal stop (ruler) automatically moves the cut material to the new value of the cut width.

Advantages:

The rear stop of the machine allows easy and quick adjustment of the cutting width. The values can be selected automatically using three program systems:

- Absolute setting – allows automatic travel to the selected value of the material width

- Chain settings – automatic feed by the specified value (decrease of the total width + cutting joint)

- Optimization system – automatic combination of widths in the material according to the operator default values (width optimization for maximum yield).

- All types of control are included in the standard version of the machine.

- Infinitely adjustable blade feed at a speed of 0 – 80 m / min. guarantees high cutting performance.

- Continuous feed speed control via foot pedal or machine panel control.

- Blade stroke control ensures a clean cut and a well-cut surface.

- Saw blade replacement is easy and safe – quick release of the saw blade.

- The saw is equipped with a laser, the beam of which marks the cutting path on the material and allows precise cutting. FLS ARROW II – represents durability and precision. The robust and rigid welded frame of the machine is made as a self-supporting steel construction with a central support and a large clear height, together with the precise guidance of the saw unit is a guarantee of long life.

Possible extension:

- Pneumatic pressure 3000 mm (can be multiplied by the cutting length of the machine)

- Increasing the cutting width up to 3000 mm

- 15 kW motor

- metal rollers

- metal plate with 6 rolls

- chains for material handling in the machine table

- bridge rear stop (allows loading of material from the back of the machine)

- cross table – base + measuring

- cross table – additional

Technical data of the FLS ARROW machine:

- Engine 11kW (15kW, 18.5 kW, 22 kW, options), 2900 rpm.

- Cutting height standard 0 -210 mm / (0-300 mm options)

- Saw blade Ø 500 to 650 mm / (Ø 900 mm)

- Clamping diameter of the disc Ø 80 mm

- Adjustable feed speed to the cut 0 – 80 m / min

- Standard cutting length 2.2 m – 6.2 m

- Standard cutting width 450 mm (options up to 3000 mm)

- Working height 850 ± 50 mm

- External dimensions length = cutting length + 2200 mm

- width = 1350/1400 mm

- Suction tunnel neck 2x 160 mm

- Required suction speed 25 – 30 m / s

- Air pressure connection 0.8 MPa

- Electricity connection 400 V / 3/50 Hz

- Delivery time: 8 – 12 weeks from the order (depends on the final version of the machine)

- Payment terms: Deposit 30% of the value of the machine and 70% before delivery of the machine

- Email: info@profixrd.sk

Reviews

There are no reviews yet.